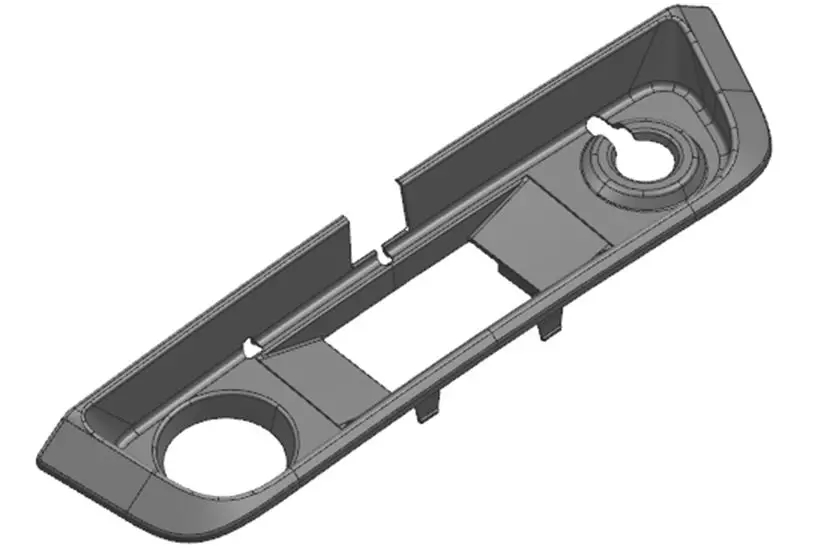

It is rare to see products with a slanted top in the slider of an injection mold, and the structure is also diversified. I will introduce a classic mechanism with a slanted top in the slider, hoping to play a role in attracting ideas.

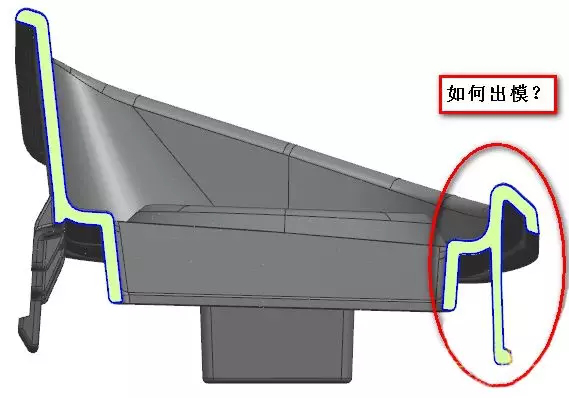

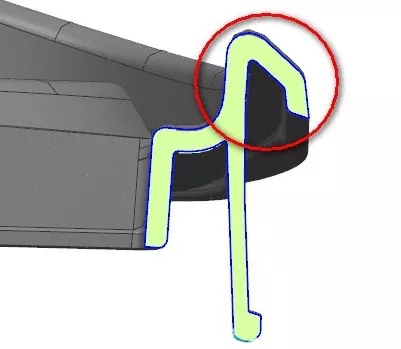

1.Design Ideas

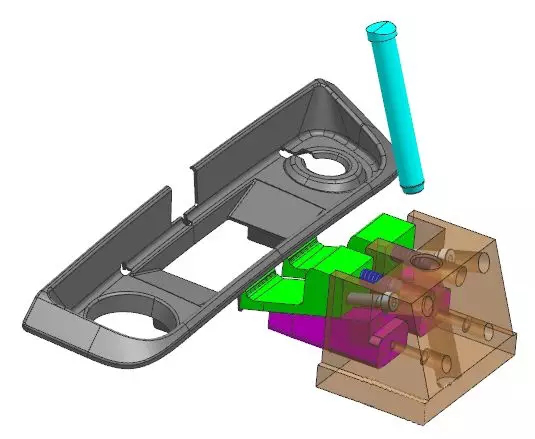

With ordinary sliding block mechanism, the steel material of the red frame is stuck and cannot be ejected from the mold. The steel material of the red frame must be pulled out of the product first and then the undercut.

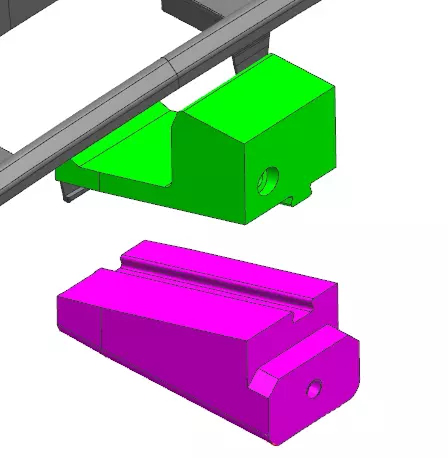

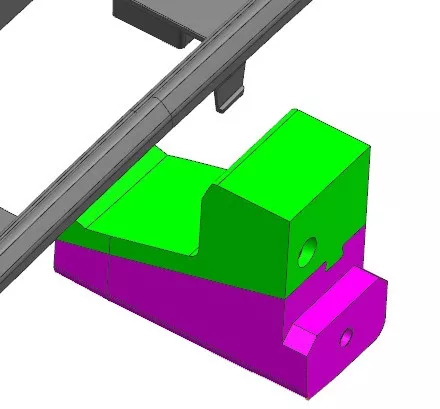

2. Slider head design

Green is the inclined top, with protruding dovetail, and magenta is the slider. It is mainly used to pull out the inverted buckle and drive the inclined top to trip down, and the dovetail groove is sliding.

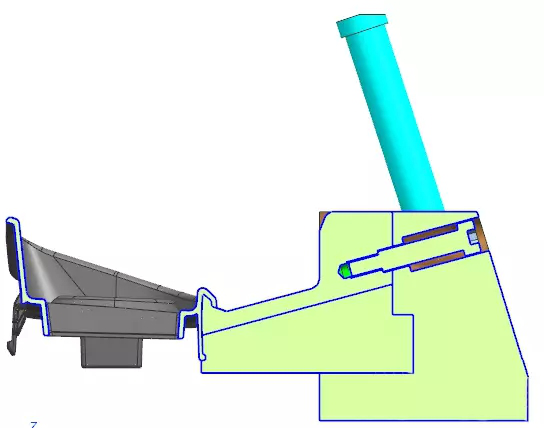

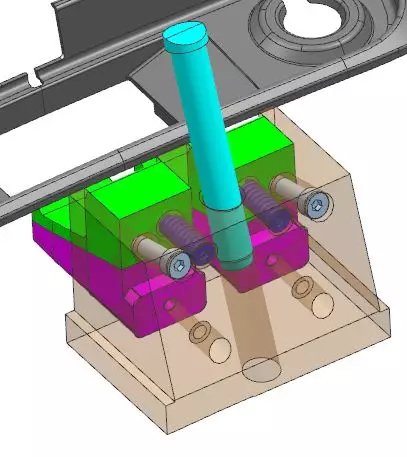

3. Anatomy of the sliding top mechanism The inclined top needs to lock a limit screw to limit the downward movement distance of the inclined top. The spring is to prevent the inclined top from following the slider to go to the right.

4. The operation principle of the slide-out sloping top mechanismThe inclined guide column drives the slider to pull the core to the right. The magenta slider insert drives the inclined top to move downwards, while disengaging the undercut. The spring prevents the inclined top from following the slider to the right. After reaching a certain distance, the limit screw Limited dead, the inclined top is pulled core with the slider at the same time.

Post time: Oct-15-2021